Printing technology has come a long way since its inception, and today, it is widely used in various industries. From creating consumer products to designing prototypes, printing has become an essential tool for businesses and individuals alike. The use cases for printing technology are diverse and continue to expand as new innovations emerge.

One of the most significant benefits of printing technology is its versatility. It can be used to create a wide range of products, from simple household items to complex industrial parts. The technology has also enabled businesses to streamline their production processes, reducing costs and increasing efficiency. As a result, printing technology has become an indispensable tool for businesses looking to stay competitive in today’s fast-paced market.

Another significant advantage of printing technology is its ability to create customized products. With 3D printing, for example, businesses can create products that are tailored to the needs of their customers. This level of customization not only enhances the customer experience but also allows businesses to differentiate themselves from their competitors. As printing technology continues to evolve, the possibilities for customization are only going to increase.

Key Takeaways

- Printing technology has become an essential tool for businesses and individuals alike, with a wide range of use cases.

- The versatility of printing technology has enabled businesses to streamline their production processes, reduce costs, and increase efficiency.

- Printing technology allows for customized products, enhancing the customer experience and providing a competitive edge.

Basics of 3D Printing

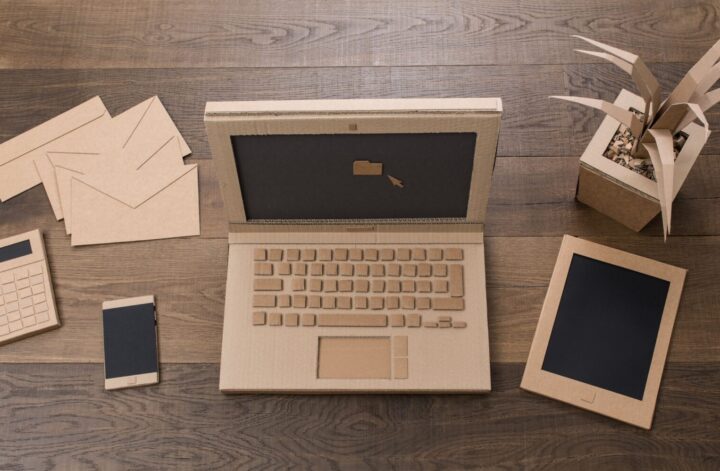

3D printing is a type of additive manufacturing that creates three-dimensional objects from a digital file. This technology has revolutionized the manufacturing industry by allowing complex shapes and designs to be produced quickly and easily. In this section, we will cover the basics of 3D printing, including the technology, additive manufacturing processes, and materials used.

3D Printing Technology

There are several types of 3D printing technologies, including stereolithography, selective laser sintering (SLS), polyjet, fused deposition modeling (FDM), and multi jet fusion (MJF). Each technology has its own advantages and disadvantages, depending on the specific application.

Additive Manufacturing Processes

Additive manufacturing is the process of creating three-dimensional objects by adding layers of material on top of each other. This process is different from traditional manufacturing techniques, such as machining or casting, which remove material to create a shape. Additive manufacturing allows for greater design flexibility and can produce complex shapes that would be impossible to create with traditional techniques.

Materials Used in 3D Printing

The materials used in 3D printing vary depending on the technology and application. Common materials include plastics, metals, ceramics, and composites. Some 3D printers can use multiple materials, allowing for the creation of objects with different properties and characteristics.

Overall, 3D printing technology has revolutionized the manufacturing industry by allowing for greater design flexibility and faster production times. As the technology continues to evolve, it is expected to become even more widespread and accessible, enabling more companies and individuals to take advantage of its benefits.

Design and Modeling

In the world of printing, design and modeling are crucial components that enable the creation of intricate and geometric designs. These designs can be used for various purposes, such as creating prototypes or producing final products. In this section, we will explore the use cases of design and modeling in printing.

CAD Models and Software

Designers and engineers use Computer-Aided Design (CAD) software to create 3D models of their designs. These models can then be used to create prototypes or final products. CAD software allows designers to create intricate designs and make modifications quickly and easily. It also enables them to test their designs before production, saving time and money.

From Concept to Prototype

Design and modeling are essential in the process of creating prototypes. Designers and engineers use CAD software to create 3D models of their designs, which can then be printed using a 3D printer. This allows them to test their designs and make any necessary modifications before moving on to production.

Geometric and Intricate Designs

Printing allows for the creation of intricate and geometric designs that would be challenging or impossible to produce using traditional manufacturing methods. Designers can use CAD software to create complex designs that can be printed with precision. This opens up new possibilities for product design and innovation.

In conclusion, design and modeling are crucial components in the printing process. CAD software allows designers and engineers to create intricate designs and test them before production, saving time and money. Printing enables the creation of geometric and intricate designs that would be difficult to produce using traditional manufacturing methods.

Industrial Applications

Printing technology has revolutionized the manufacturing industry, enabling faster and more efficient production of complex parts and components. Industrial applications of printing are diverse and range from aerospace to medical devices. Here are some of the most notable industrial use cases of printing technology.

Aerospace and Automotive

Printing technology has found its way into the aerospace and automotive industries, where it is used to produce complex components that were previously impossible to manufacture. Additive manufacturing techniques, such as selective laser sintering (SLS) and fused deposition modeling (FDM), are used to produce lightweight and high-strength parts for aircraft and automobiles. The parts produced through printing are not only lighter but also more durable and resistant to wear and tear.

Construction and Architecture

Printing technology is also being used in the construction and architecture industries to produce large-scale structures and buildings. The use of 3D printing in construction has the potential to revolutionize the industry by reducing the time and cost of construction while improving the quality and precision of the finished product. Printing technology is also used to produce architectural models and prototypes, allowing architects to visualize and test their designs before construction begins.

Medical Devices and Prosthetics

Printing technology has also found significant use in the medical industry, where it is used to produce customized prosthetics, dental implants, and patient-specific surgical guides. Additive manufacturing techniques, such as stereolithography (SLA), are used to produce highly precise and accurate medical devices that are tailored to the patient’s specific needs. Printing technology has also enabled the production of complex medical implants and devices that were previously impossible to manufacture.

In conclusion, printing technology has found significant use in various industrial applications, including aerospace, automotive, construction, architecture, and medical devices. The technology has enabled faster and more efficient production of complex parts and components while reducing the time and cost of manufacturing. As the technology continues to evolve, it is expected to find even more diverse applications in the manufacturing industry.

Consumer Products

Printing technology has revolutionized the way consumer products are manufactured and personalized. From fashion and jewelry to home goods and electronics, printing has enabled manufacturers to create unique and customized products for their customers. This section explores some of the use cases of printing technology in consumer products.

Fashion and Jewelry

Printing technology has transformed the fashion and jewelry industry by enabling manufacturers to create unique and personalized designs. With 3D printing, jewelry designers can create intricate and complex designs that were previously impossible to manufacture using traditional methods. Printing technology has also made it possible for fashion designers to create custom fabrics and prints, allowing them to create one-of-a-kind pieces that stand out from the crowd.

Home Goods and Electronics

Printing technology has enabled manufacturers to create custom home goods and electronics that cater to the specific needs and preferences of their customers. For example, printing technology can be used to create custom phone cases, laptop covers, and other electronic accessories. It can also be used to create custom home decor items such as lampshades, vases, and picture frames.

Personalized Items

Printing technology has made it possible for consumers to personalize a wide range of items, from glasses and shoes to clothes and bags. With printing technology, customers can add their own designs, logos, and text to their favorite items, creating unique and personalized products that reflect their personality and style.

In conclusion, printing technology has transformed the way consumer products are manufactured and personalized. It has enabled manufacturers to create unique and customized products that cater to the specific needs and preferences of their customers. With the continued development of printing technology, we can expect to see even more innovative and exciting use cases in the future.

Innovations in 3D Printing

As 3D printing technology continues to evolve, new and exciting use cases continue to emerge. Here are a few examples of how 3D printing is being used to push the boundaries of what’s possible:

Bioprinting and Tissue Engineering

One of the most promising applications of 3D printing is in the field of bioprinting and tissue engineering. Researchers are using 3D printers to create complex structures that mimic the architecture of human organs and tissues. This technology has the potential to revolutionize the field of medicine, allowing doctors to create custom-made replacement organs for patients in need.

3D Printing in Space Exploration

3D printing is also being used to support space exploration efforts. NASA has installed a 3D printer on the International Space Station, which allows astronauts to create tools and replacement parts on-demand. This technology is particularly useful in space, where it can take months or even years to transport supplies from Earth.

Food 3D Printing

3D printing is even being used to create food. Companies are using 3D printers to create intricate designs and shapes out of edible materials, such as chocolate and dough. This technology has the potential to transform the food industry, allowing chefs to create unique and visually stunning dishes.

Overall, these innovations in 3D printing are just the beginning. As the technology continues to evolve, we can expect to see even more exciting use cases emerge in the years to come.

Business and Education

In-House 3D Printing

In-house 3D printing has become increasingly popular for businesses and educational institutions alike. With the ability to create prototypes, models, and even final products in-house, companies can save time and money while also maintaining control over their production process. In-house 3D printing also allows for customization and quick iteration, enabling businesses to respond quickly to market demands.

Educational institutions are also taking advantage of in-house 3D printing to enhance their curricula. Students can design and print their own prototypes, allowing for hands-on learning and a deeper understanding of design and engineering principles. In-house 3D printing also allows for the creation of specialized tools and equipment, giving students access to resources that may not be available otherwise.

3D Printing for Training and Specialization

In addition to in-house production, 3D printing is also being used for training and specialization in both business and education. Companies can use 3D printing to create training models and simulations, allowing employees to practice and refine their skills in a safe and controlled environment. 3D printing can also be used to create specialized tools and equipment for specific job functions, improving efficiency and safety.

Educational institutions are also using 3D printing for training and specialization. Students can use 3D printing to create models and simulations for training purposes, as well as to create specialized tools and equipment for their chosen career paths. This allows for a more hands-on and practical approach to education, preparing students for real-world scenarios.

Impact on Traditional Manufacturing

The rise of 3D printing has had a significant impact on traditional manufacturing processes. With the ability to create complex shapes and designs quickly and easily, 3D printing has disrupted traditional manufacturing methods. However, traditional manufacturing still has its place in many industries, particularly for large-scale production and specialized materials.

Businesses and educational institutions must consider the benefits and drawbacks of 3D printing versus traditional manufacturing when deciding on their production processes. While 3D printing offers many advantages, it may not be the best option for every situation.

In conclusion, in-house 3D printing, 3D printing for training and specialization, and the impact on traditional manufacturing are all important use cases for businesses and educational institutions. By understanding the benefits and limitations of 3D printing, companies and schools can make informed decisions about their production processes and prepare their employees and students for the future of manufacturing.

Environmental Impact and Sustainability

Eco-Friendly Materials

Printing technology has come a long way, and so have the materials used in the process. Today, there are several eco-friendly materials available that can be used in printing. These materials are made from renewable sources, such as cornstarch, sugarcane, and bamboo. They are biodegradable and compostable, making them an excellent choice for environmentally conscious businesses.

In addition to being eco-friendly, these materials also offer several benefits. For instance, they are lightweight, durable, and can be printed in a wide range of colors. They are also cost-effective, which makes them an attractive option for businesses looking to reduce their carbon footprint without breaking the bank.

Reducing Waste with Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a process that involves building a three-dimensional object layer by layer. This process is highly efficient and can significantly reduce waste compared to traditional manufacturing methods. With additive manufacturing, businesses can produce only what they need, eliminating the need for excess inventory and reducing waste.

Moreover, additive manufacturing also allows for the use of recycled materials. This means that businesses can use waste materials, such as plastic bottles, to create new products. This not only reduces waste but also helps to conserve resources and reduce the environmental impact of manufacturing.

In conclusion, printing technology can have a significant impact on the environment. However, by using eco-friendly materials and additive manufacturing, businesses can reduce their carbon footprint and contribute to a more sustainable future.

Challenges and Future Outlook

Limitations of Current 3D Printing Technologies

Despite the numerous benefits of 3D printing, there are still limitations that need to be addressed. One of the main challenges is achieving higher precision and accuracy. While current 3D printing technologies can produce complex shapes and designs, the accuracy and precision are still not at the level required for certain applications, such as in the medical and aerospace industries.

Another limitation is the availability of metal 3D printing. Although metal 3D printing has been around for some time, it is still not widely available and is often expensive. This limits its use in industries that require metal parts, such as the automotive and aerospace industries.

Potential for Future Advancements

Despite the limitations, there is great potential for future advancements in 3D printing technology. One area of focus is the development of faster and more efficient 3D printing methods, such as rapid prototyping. This will allow for faster production of prototypes and products, ultimately reducing costs and improving efficiency.

Another area of focus is the development of more advanced metal 3D printing technologies. This will allow for the production of high-quality metal parts at a lower cost, making it more accessible to a wider range of industries.

In conclusion, while there are still challenges and limitations to overcome, the future of 3D printing looks promising. With continued research and development, it is expected that 3D printing will become even more efficient, accurate, and accessible, opening up new possibilities for industries and consumers alike.

Frequently Asked Questions

What are the primary applications of 3D printing in the medical field?

3D printing technology has revolutionized the medical industry by providing customized solutions for various medical applications. The primary applications of 3D printing in the medical field include creating personalized prosthetics, implants, and surgical models. Surgeons can use 3D printed models to plan and practice complex surgeries, reducing the risk of complications during the actual operation.

How has 3D printing technology impacted the manufacturing industry?

3D printing has transformed the manufacturing industry by enabling the production of complex geometries that were previously impossible to manufacture. It has also reduced the lead time for manufacturing and eliminated the need for costly tooling. Companies can now produce small batches of customized products at a lower cost, making it easier for startups to enter the market.

What are some real-life products that are currently being produced with 3D printing?

3D printing is being used to produce a wide range of products, including prosthetics, dental implants, aerospace components, and even cars. Companies like Adidas and Nike are using 3D printing to create customized shoes for their customers. In the medical field, 3D printing is being used to create patient-specific implants and surgical models.

In what ways is 3D printing being utilized in home environments?

3D printing technology has made it possible for individuals to create customized products at home. People can design and print their own toys, jewelry, and even furniture. 3D printing is also being used to create replacement parts for household appliances and electronics.

Can you list the potential future advancements in 3D printing technology?

The future of 3D printing technology looks promising, with potential advancements in areas such as printing speed, material options, and printing resolution. Scientists are also exploring the use of 3D printing to create human organs and tissues, which could revolutionize the medical industry.

What are the most innovative uses of 3D printing across various industries?

The most innovative uses of 3D printing across various industries include creating customized medical implants, printing food, and even constructing buildings. In the fashion industry, designers are using 3D printing to create unique and complex designs. The technology is also being used to create sustainable and eco-friendly products.