Introduction

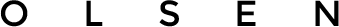

Printing technology has evolved significantly over the years, from traditional ink and paper printing to cutting-edge 3D printing. With a wide range of materials available for printing, it can be overwhelming to choose the right one for your specific project. In this comprehensive guide, we will explore the various printing materials, their characteristics, and their applications. Whether you are a hobbyist, artist, engineer, or entrepreneur, this article will help you make informed decisions when it comes to selecting the perfect material for your printing needs.

Table of Contents

- Types of Printing Materials

- Paper-Based Materials

- Synthetic Materials

- Metal-Based Materials

- Bioprinting Materials

- Conclusion

1. Types of Printing Materials

When it comes to printing, there is a wide array of materials to choose from, each catering to different requirements and applications. The choice of material depends on factors such as durability, flexibility, texture, color, and cost. Let’s delve into the different categories of printing materials.

2. Paper-Based Materials

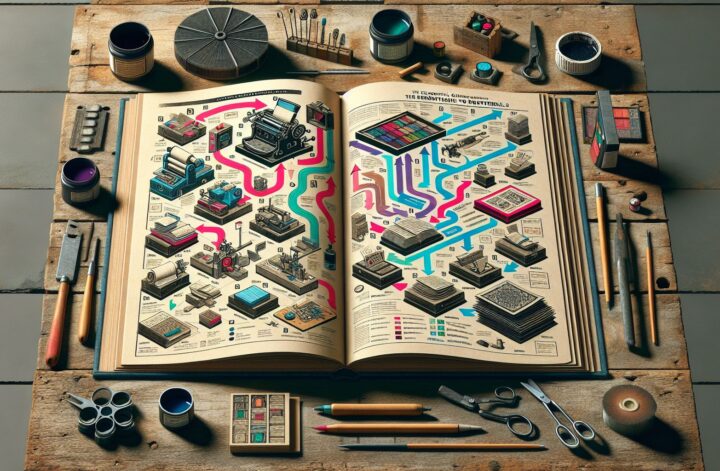

One of the most commonly used printing materials for traditional printing methods is paper. Paper is versatile, widely available, easy to print on, and cost-effective. It is suitable for a range of applications, including books, magazines, brochures, and posters. However, not all papers are created equal. Different paper types, such as coated, uncoated, and specialty papers, offer distinct features and finishes.

Coated papers, such as glossy or matte finishes, provide a smooth and polished look, making them ideal for vibrant images, photographs, and promotional materials. Uncoated papers, on the other hand, have a natural and textured surface, making them suitable for books, letterheads, and business cards. Specialty papers, including handmade or recycled papers, add uniqueness and sustainability to printed materials.

3. Synthetic Materials

In addition to paper, synthetic materials have gained popularity due to their unique properties. Synthetic materials are resistant to moisture, tear, and wear, making them suitable for commercial printing applications such as outdoor signage, banners, and labels. These materials include vinyl, polyester, polypropylene, and polyethylene.

Vinyl is a popular choice for outdoor signage as it is weather-resistant and provides excellent color reproduction. Polyester, commonly known as Mylar, is durable, transparent, and can be used for applications such as blueprints and overhead transparencies. Polypropylene and polyethylene are known for their flexibility, making them ideal for products such as banners, packaging, and retail displays.

4. Metal-Based Materials

Metal-based printing materials have revolutionized the field of manufacturing and product development. With the advent of 3D printing, it is now possible to create complex metal objects that were once challenging and time-consuming to manufacture. Metal materials commonly used in 3D printing include stainless steel, titanium, aluminum, and bronze.

Stainless steel offers high strength and corrosion resistance, making it suitable for functional parts, jewelry, and architectural models. Titanium, known for its lightweight and excellent mechanical properties, is widely used in aerospace, medical, and automotive industries. Aluminum is another popular choice due to its low density, thermal conductivity, and malleability. Bronze, a copper-based alloy, is widely used for artistic applications such as sculptures and decorative items.

5. Bioprinting Materials

Bioprinting, a cutting-edge field that combines engineering with biology, has revolutionized the medical and pharmaceutical industries. Bioprinting materials involve the deposition of living cells, biomaterials, and growth factors to fabricate functional tissues and organs. These materials, commonly referred to as bioinks, must be biocompatible, provide structural support, and allow cell proliferation.

Bioinks are often composed of natural materials such as alginate, collagen, hyaluronic acid, and synthetic polymers like polyethylene glycol (PEG). Alginate, derived from seaweed, forms hydrogels and provides a 3D structure for cell growth. Collagen, a major protein found in the human body, offers excellent biocompatibility and supports cell adhesion. Hyaluronic acid, a key component of the extracellular matrix, promotes tissue regeneration. PEG, a synthetic polymer, provides mechanical stability and regulates cellular interactions.

Conclusion

When it comes to printing, the choice of material plays a crucial role in achieving the desired outcome. Whether it’s traditional printing on paper or pushing the boundaries of 3D printing with metals and bioprinting, understanding the properties and applications of various materials is essential. Consider the durability, flexibility, texture, color, and cost when selecting the right material for your printing project.

Remember, the world of printing materials is vast, and technological advancements continue to introduce newer options. Stay updated with the latest developments and experiment with different materials to unlock endless possibilities in the world of printing. The choice is not just about what you print, but also how you print it, using the perfect material for a flawless result.