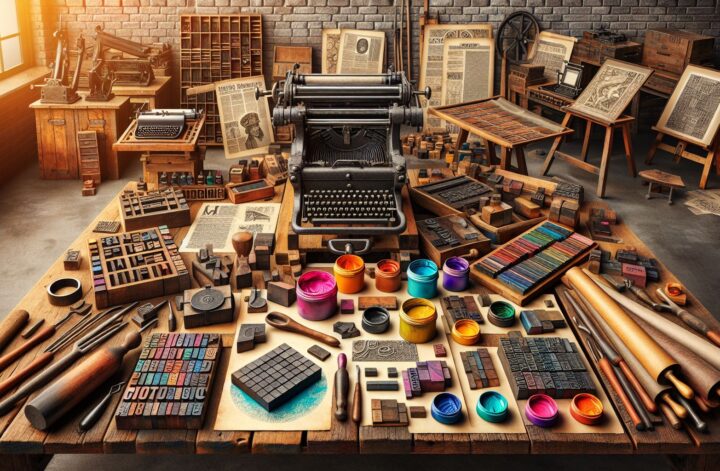

Imagine a world without printing materials – a world where documents could not be instantly duplicated, and books could not be effortlessly produced. The printing industry has come a long way since its humble beginnings, with technological advancements allowing for the development of innovative materials that enhance both the efficiency and quality of the printing process. From the ancient Egyptians’ papyrus scrolls to today’s cutting-edge 3D printing filaments, let’s explore the fascinating journey of printing materials, how they have evolved over time, and the impact they have had on the way we communicate and create.

Unleashing the Power of the Written Word: From Papyrus to Paper

The art of printing can be traced back over five thousand years to the ancient Egyptians. Their primary printing material was papyrus, a plant-based material that proved to be a significant advancement in recording information. Papyrus was lightweight, easy to transport, and had a relatively smooth surface, making it ideal for writing with a reed pen or brush. The invention of papyrus enabled ancient civilizations to efficiently document their histories, literature, and various cultural aspects.

While papyrus was a significant breakthrough, it was soon replaced with the advent of papermaking techniques. The Chinese developed the first true paper around 105 AD, made from a mixture of mulberry bark, old rags, and hemp waste. The quality and abundance of paper surpassed that of papyrus, leading to the emergence of books, newspapers, and an explosion in global literacy rates.

Paper, in its many forms, remained the primary medium for printing until the late 20th century. However, with technological advancements and the rise of digital communication, new forms of printing materials began to emerge.

The Digital Revolution: From Inkjet to Toner

As computers entered our homes and workplaces, the way we perceive and utilize printing materials drastically transformed. The birth of the inkjet printer in the 1980s revolutionized personal printing. Inkjet printers, like their name suggests, sprayed small droplets of ink onto paper to recreate digital files. Traditional paper remained the dominant printing material, but advancements in inkjet technology allowed for printing on various surfaces and substrates, expanding the possibilities of printing materials.

Around the same time, laser printers gained popularity due to their ability to produce higher resolution prints, faster speeds, and sharper text compared to inkjet printers. Unlike inkjet printers, which utilized liquid ink, laser printers used toner – a fine, dry powder composed of particles that are attracted to electrical charges, creating crisp, smudge-resistant prints.

The introduction of laser printers and toner marked a significant turning point in printing materials, providing businesses with cost-effective and high-quality printing solutions. However, even these advancements were just the beginning of a more transformative era yet to come.

A New Dimension of Printing: The Rise of 3D Printing

As technology continued to advance, the printing industry witnessed the emergence of a groundbreaking new concept – 3D printing. Also known as additive manufacturing, 3D printing allows for the creation of three-dimensional objects from digital files. This innovative technology opened up endless possibilities across a wide range of applications, from manufacturing and engineering to medicine and even fashion.

In the world of 3D printing, the printing material takes center stage. Unlike traditional printing methods, 3D printers utilize various materials, often referred to as filaments, to construct objects layer by layer. These filaments come in different types, each offering unique characteristics and functionalities.

PLA (Polylactic Acid)

One of the most popular 3D printing materials is PLA, a biodegradable and bioactive thermoplastic derived from renewable resources like cornstarch or sugarcane. PLA exhibits excellent print quality and low warping, making it an ideal choice for beginners or anyone looking to explore 3D printing at home. While it might not have the same mechanical strength as other materials, PLA’s eco-friendly nature and ease of use make it a favorite among hobbyists.

ABS (Acrylonitrile Butadiene Styrene)

ABS is another commonly used 3D printing material, known for its strength, durability, and high-temperature resistance. This petroleum-based thermoplastic is particularly suited for functional prototypes, mechanical parts, and objects subjected to wear and tear. However, ABS can generate unpleasant odors when heated, so adequate ventilation is crucial during printing.

PETG (Polyethylene Terephthalate Glycol)

PETG, a variant of the widely used PET (Polyethylene Terephthalate), combines the strength and durability of its parent material with increased flexibility and ease of printing. PETG is an excellent choice for mechanical parts, storage containers, and objects requiring impact resistance without sacrificing print quality. It also offers transparency and a glossy finish, making it suitable for decorative prints.

Nylon and Other Specialty Filaments

Beside the more commonly used filaments, the world of 3D printing offers an array of specialty materials catering to specific industries and applications. Nylon is a common choice for creating parts that require high durability and flexibility, making it popular in engineering and robotics. Other specialty filaments include wood-filled PLA, flexible TPU (Thermoplastic Polyurethane), conductive filaments, and even food-safe materials like PCL (Polycaprolactone).

The vast range of 3D printing materials allows for unparalleled creativity and customization, enabling inventors, designers, and engineers to bring their ideas to life with ease and precision.

Pushing the Boundaries: Printing Beyond Traditional Materials

While paper, ink, and filaments form the foundation of printing materials, future possibilities are pushing the boundaries of what can be used for printing. Researchers around the world are exploring innovative materials to create everything from living tissues to solar cells.

Nanomaterials

One promising area of research focuses on the use of nanomaterials, which have unique properties due to their incredibly small size. Nanomaterials, such as graphene, carbon nanotubes, and quantum dots, have the potential to revolutionize printing by enabling the production of highly efficient electronics, flexible displays, and even durable and lightweight materials for space exploration.

Bioinks

In the field of bioprinting, scientists are working on developing bioinks – materials that can replicate the properties of human tissues and organs. Combining living cells with a supportive matrix, bioinks could pave the way for printing functional organs, artificial skin, and even 3D-printed food.

Solar Inks

Advancements in the field of solar energy have led to the development of solar inks – materials capable of converting light into electricity. Printing solar cells on flexible substrates using these inks opens up possibilities for lightweight and customizable solar panels, integrating renewable energy into everyday objects like clothing, backpacks, and even buildings.

The potential for printing materials seems limitless, with ongoing research and innovation continuously pushing us towards new frontiers.

Conclusion

From the ancient Egyptians’ papyrus scrolls to the groundbreaking 3D printing filaments of today, printing materials have evolved in tandem with human creativity and technological advancements. The journey from papyrus to paper revolutionized the way we communicate and paved the way for knowledge to be shared on a global scale. As digital printing emerged, inkjet and laser printers introduced us to new possibilities, making high-quality